Description

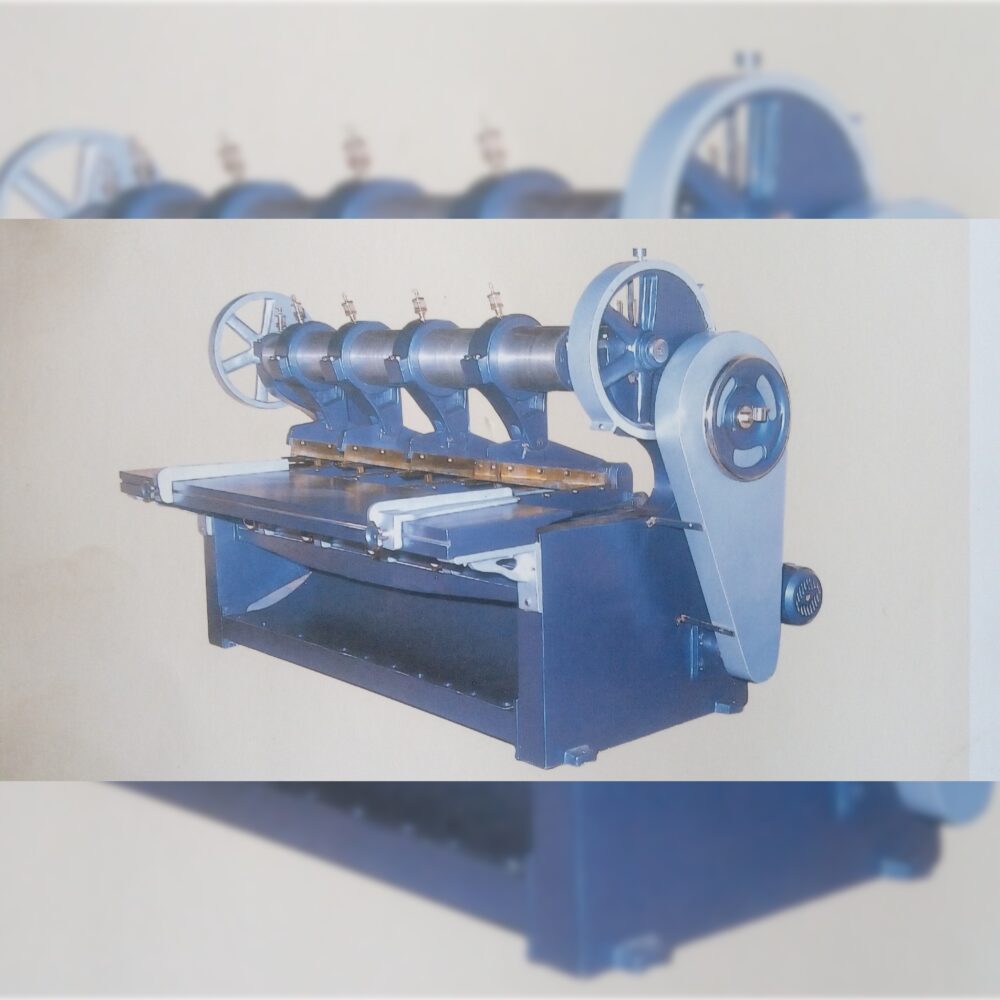

The Paper Plate Machine is an advanced, high-efficiency device designed for the automated production of paper plates. Engineered to handle various sizes and designs, this machine streamlines the process of creating durable, eco-friendly plates used for food service, events, and packaging. Featuring precise cutting, pressing, and shaping mechanisms, the paper plate machine ensures high-quality output with minimal labor. Ideal for both small-scale and large-scale production, it combines speed, reliability, and versatility in a single robust unit.

Key Features:

- Automated Production: Fully automated process from feeding paper to final plate output, reducing labor costs and increasing production efficiency.

- Adjustable Molds and Dies: Accommodates different plate sizes and shapes with interchangeable molds and dies, providing versatility for various applications.

- High-Speed Operation: Capable of producing a high volume of plates per hour, ensuring fast turnaround times and increased productivity.

- Precision Pressing Mechanism: Utilizes advanced pressing technology to ensure uniform thickness and strength of the paper plates, enhancing durability.

- Durable Construction: Built with high-quality materials and components to withstand continuous operation and ensure long-term reliability.

- User-Friendly Interface: Features an intuitive control panel for easy operation, allowing quick adjustments and monitoring of the production process.

- Eco-Friendly Production: Utilizes recyclable paper materials, contributing to sustainable practices and reducing environmental impact.

Applications:

- Food Service Industry: Ideal for producing disposable plates for restaurants, catering services, and food trucks.

- Event Planning: Suitable for creating plates for parties, weddings, and other events where disposable tableware is needed.

- Packaging Industry: Can be used for manufacturing paper plates for packaging and serving purposes.

Benefits:

- Increased Efficiency: Automated production and high-speed operation reduce manual labor and increase output, leading to cost savings.

- Versatility: Adjustable molds and dies allow for customization of plate sizes and designs, meeting diverse customer needs.

- Consistent Quality: Precision pressing ensures uniform plate quality, enhancing product reliability and customer satisfaction.

- Sustainability: The use of recyclable paper materials supports eco-friendly practices, appealing to environmentally conscious consumers.

The Paper Plate Machine from Krishna Print and Pack offers a high-efficiency, automated solution for producing a wide range of paper plates. Combining speed, precision, and eco-friendly technology, this machine is perfect for manufacturers seeking to enhance productivity and quality in their paper plate production processes.